Hamerz approaches building energy infrastructures as an integrated whole, studying all systems to understand how they interact and how they could operate at peak performance. This total approach generates significantly higher savings and long-term value and provides attractive opportunities to renew critical assets while improving indoor environments.

The building automation system and industrial automation can leverage data that it collects to help reduce costs and significantly transform how buildings and factories operate.

Benefits of building automation:

Lower operational costs:

A smart building automation system can leverage data that it collects to help reduce costs. For example, it can help reduce the use of electric lighting by adjusting shades to let in more natural light. Such lighting management has been proved to lower power usage dramatically.

Lower energy costs:

Connecting building equipment such as lighting, shades, and HVAC systems enables building operators to automatically adjust temperature, shades, and lighting based on time of day and occupancy. In turn, buildings can become more energy-efficient to meet or exceed stringent regulations for greenhouse-gas emissions.

More flexibility to adjust workspaces:

Smart building data can be used, for example, to detect changes in occupancy density. The building's HVAC systems then adjust airflow, humidity, and temperature appropriately.Or lighting color could change to indicate too many people in a conference room, workspace, or building when the space's occupancy exceeds density thresholds.

Building data can also support automated scheduling, from parking-space allocation to workspace assignment to conference room reservation

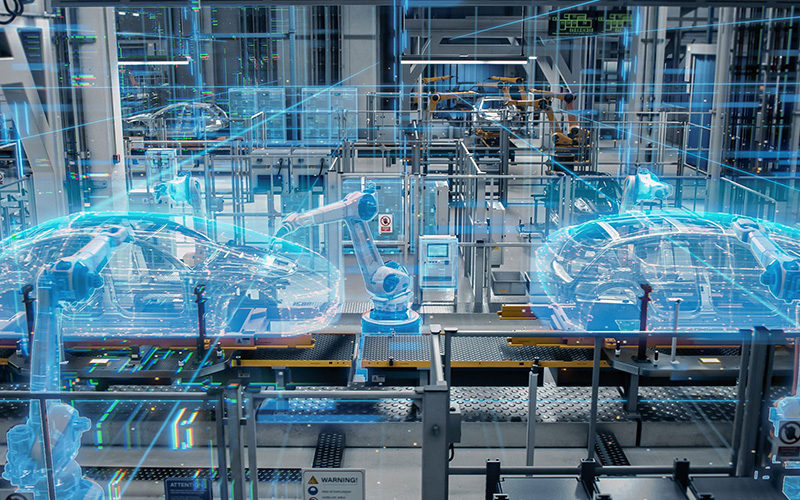

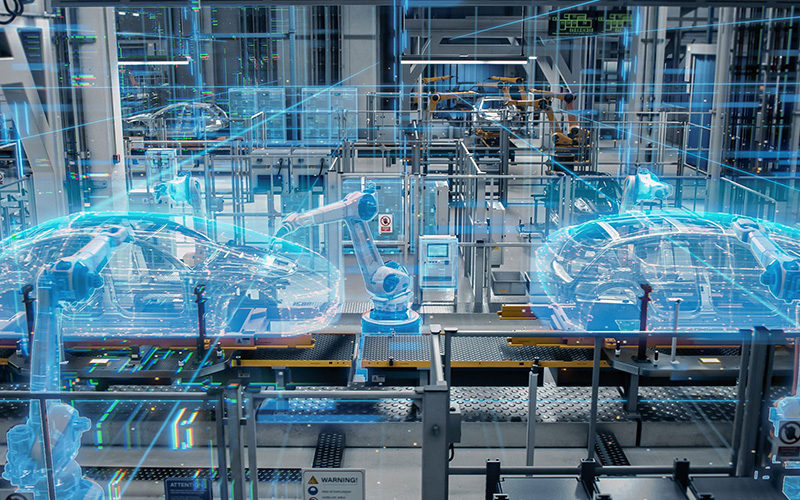

Industrial Automation:

Industrial control and factory automation have revolutionized modern manufacturing processes, bringing about a significant transformation in the way factories operate. These two components enhance efficiency, productivity, and safety within industrial settings. Industrial control entails the utilization of advanced technologies like programmable logic controllers (PLCs), sensors, and human-machine interfaces (HMIs) to monitor and regulate machinery and processes. On the other hand, factory automation involves integrating automated systems and equipment to carry out tasks traditionally performed by human operators. By reducing manual labor and optimizing production quality, industrial control, and factory automation aim to streamline operations, minimize errors, and expedite time-to-market for products.

Energy Consulting :

amerz’s experts in energy consulting have the extensive industry and operational expertise required to help our clients prosper under pressure to reduce operational costs and improve sustainable practices. Our team of professional engineers and consultants work and collaborate with client stakeholders to determine and meet their specific energy goals, while maintaining optimal comfort for tenants.

With incentive rules changing it can be difficult to target the highest return energy conservation measures. Hamerz helps clients to anticipate where the industry is heading, to pinpoint opportunities and strategize for the future. We leverage deep industry expertise and extensive project experience to deliver powerful solutions that meet each client’s needs.

Additionally, we perform Commercial Building Energy Modeling, which constructs engineering and economic models to represent the performance of buildings in order to evaluate and quantify the impact of policy, design, retrofit, and operational decisions. All of these positions have an impact on the process of producing efficient and sustainable buildings

Address: Unit: 6, NO: 19,Ghoba Street, Shariati Street,Tehran/Iran

Call: (+98)21-22883163

Email: Info@hamerz-co.ir